Ergonomics Evaluation of workstations

Brunello Cucinelli SPA

General Info

Ergonomics evaluation and first design phase for the workstations of the Brunello Cucinelli factory, Perugia (Italy).

Typology

Agreement between the Department of Architecture DIDA and Perugia Check up s.r.l.

Period

2014-2015

Coordination:

Francesca Tosi, Alessandra Rinaldi

Department of Architecture DIDA - University of Florence

With

Rita Berchtold

Perugia Check up s.r.l.

Collaborators

Alessia Brischetto

Daniele Busciantella Ricci

Mattia Pistolesi

PROJECT DESCRIPTION

General Objective

The general objectives of the research project were the improvement of the work environment quality and the optimization/redesign of the workstations in the prototypes laboratory of the factory.

The research was based on scientific and methodological approach of the ergonomics for design and its theoretical and operative tools.

The purpose was the elaboration of design solutions for the improvement of ergonomic quality of three operating workstations in the factory.

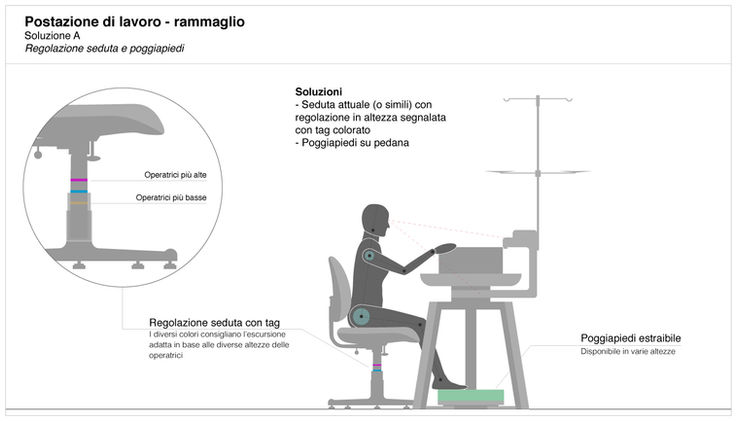

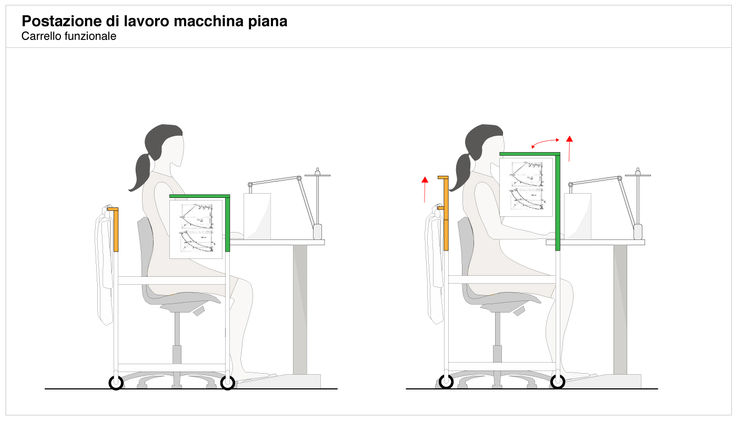

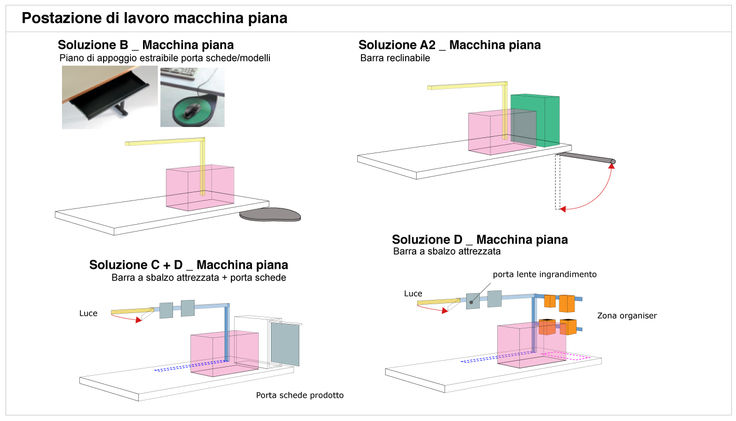

The interventions were focused on the evaluation of the operator needs and expectations according to the working activities. The workstations: flat-bed sewing machine, darning, linking machines.

All the evaluation phases were conducted in collaboration with the team of the University of Bologna Department of Medical and Surgical Sciences (F. Violante, S. Mattioli, R. Bonfiglioli).

Operating phases of the project:

Phase 1: Analysis and evaluation according to the ergonomics for design methods (for the three individuated workstations)

A) The prototyping laboratory workstations and the posture of the operators (seamstress, mender and seamstress of the flat-bed sewing machine) were studied according to the ergonomics for design and human-centred design methods: user observation and task analysis.

B) Data analysis and evaluation.

C) Conclusion and elaboration of the synthesis documentation.

Phase 2: Improvement of the analysed workstations (flat-bed sewing machine, darning, linking machines)

D) Possible solutions were individuated for a partial improvement with minimal intervention for each analysed workstation.

E) Possible solutions for each workstation were selected jointly with the company. Operative indications with drawings and graph schemes were developed.